Tungsten Heavy Alloys

Tungsten Heavy Alloys are part of a family of sintered tungsten alloys (W-Ni-Fe or W-Ni-Cu) with densities ranging between 17.0 gr/cm3 and 18.7 gr/cm3. Tungsten Heavy Alloys share the same initial Tungsten Injection Molding (TIM) manufacturing process as Poly-Tungsten however Tungsten Heavy Alloys require additional processing steps: organic binder removal (debinding) and liquid phase sintering. The final product has even higher mechanical properties in density, heat resistance and electrical conductance.

Despite having additional steps, our manufacturing process is streamlined and offers substantial cost benefits for our customers. The final product is safe and has outstanding mechanical properties for ionizing radiation protection and lead replacement.

Radiguard™ customizes Tungsten Heavy Alloys radiation shields for medical devices, medical equipment, nuclear medicine, and radiography machinery that require the especially high mechanical properties of Tungsten Heavy Alloys.

ADDITIONAL APPLICATIONS

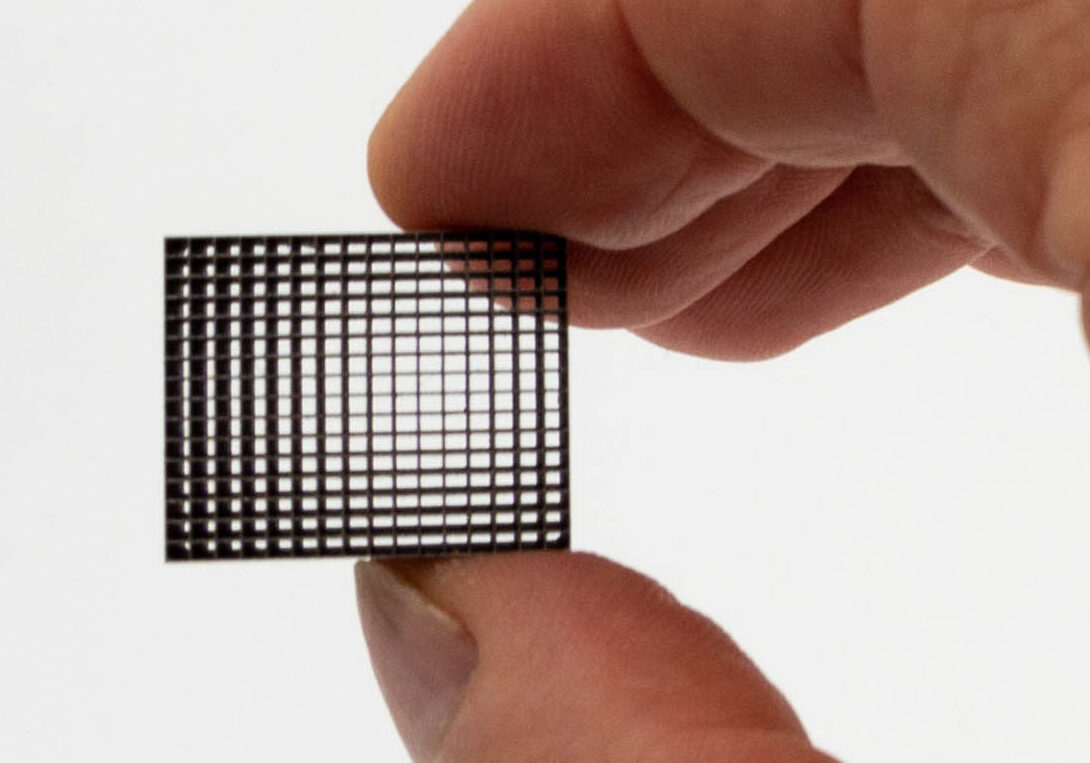

Tungsten Heavy Alloys are also suitable for weight-balancing applications in aviation and aerospace and their non-magnetic and high electrical conductance properties make it viable for heat sink application in microelectronics.